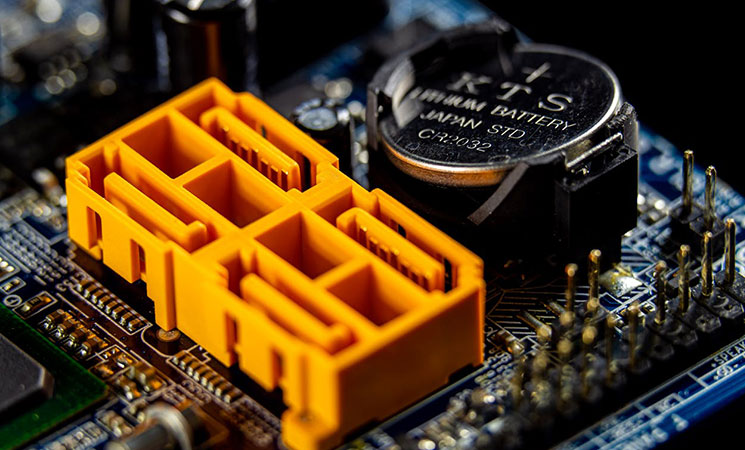

In today’s rapidly evolving technology landscape, acquiring electronic components efficiently and cost-effectively is essential for businesses to stay competitive. From sourcing quality components to optimizing procurement processes, organizations must adopt strategies that enable them to obtain the components they need while minimizing costs. In this article, we’ll explore various cost-effective solutions for electronic component acquisition, including best practices, tools, and techniques to help businesses streamline their procurement efforts and maximize value.

1. Strategic Sourcing

Strategic sourcing involves identifying the most cost-effective suppliers for electronic components based on factors such as price, quality, reliability, and lead times. By conducting thorough supplier assessments and negotiations, organizations can secure favorable pricing and terms while ensuring the quality and reliability of the components they acquire. This approach allows businesses to leverage their purchasing power and build long-term relationships with trusted suppliers, ultimately reducing costs and mitigating supply chain risks.

2. Vendor Consolidation

Consolidating vendors is another effective way to reduce parts procurement costs and streamline operations. By working with a smaller number of preferred suppliers, organizations can benefit from economies of scale, simplified invoicing and payment processes, and enhanced supplier relationships. Consolidating vendors also enables businesses to negotiate better pricing and terms by consolidating their purchasing volume with fewer suppliers, driving down costs and improving overall efficiency.

3. Inventory Optimization

Inventory optimization is critical for managing costs and minimizing excess inventory carrying costs. By leveraging demand forecasting tools and analytics, organizations can accurately predict their component requirements and maintain optimal inventory levels to meet demand without overstocking. Additionally, implementing just-in-time (JIT) inventory management practices can further reduce inventory holding costs by minimizing excess inventory and maximizing inventory turnover, ultimately leading to significant cost savings.

4. Value Engineering

Value engineering involves identifying opportunities to reduce costs without compromising product quality or performance. By evaluating alternative materials, manufacturing processes, or design specifications, organizations can identify cost-saving opportunities throughout the product lifecycle. Value engineering can help businesses optimize component costs, improve product competitiveness, and enhance overall profitability while maintaining product quality and performance standards.

5. Supplier Negotiation

Effective negotiation with suppliers is essential for securing favorable pricing, terms, and conditions for electronic components. By understanding market dynamics, benchmarking prices, and leveraging competitive bids, organizations can negotiate better deals and maximize cost savings. Additionally, establishing long-term contracts or strategic partnerships with key suppliers can provide stability, predictability, and preferential pricing, further reducing procurement costs over time.

6. Digital Procurement Tools

Digital procurement tools, such as electronic sourcing platforms, e-procurement systems, and supplier portals, can streamline the procurement process and drive cost savings. These tools enable organizations to automate sourcing, bidding, and purchasing activities, reducing manual effort, errors, and processing time. Additionally, digital procurement platforms provide real-time visibility into supplier performance, pricing trends, and market dynamics, empowering organizations to make informed decisions and optimize their procurement strategies for maximum cost-effectiveness.

7. Outsourcing

Outsourcing certain procurement functions, such as supplier management, sourcing, or logistics, can help organizations reduce costs and focus on their core competencies. By partnering with third-party procurement providers or managed service providers, businesses can leverage their expertise, resources, and economies of scale to optimize procurement processes, drive cost savings, and improve operational efficiency. Outsourcing can also provide access to specialized skills, technologies, and market intelligence, enabling organizations to stay competitive in the fast-paced electronic components market.

Conclusion

In conclusion, cost-effective solutions for electronic component acquisition are essential for organizations to remain competitive and profitable in today’s dynamic business environment. By adopting strategic sourcing practices, consolidating vendors, optimizing inventory, value engineering, negotiating effectively, leveraging digital procurement tools, and considering outsourcing options, businesses can streamline their procurement processes, reduce costs, and maximize value. By implementing these cost-effective solutions, organizations can enhance their competitiveness, improve their bottom line, and position themselves for long-term success in the electronic components market.